Home › Forums › Wooden Boat Building › Lone Star Avenger #934

- This topic has 15 replies, 5 voices, and was last updated 5 years, 7 months ago by

Jeffrey Weeber.

Jeffrey Weeber.

-

AuthorPosts

-

April 30, 2019 at 4:15 pm #11036

Ben Roper

ParticipantI’m one of the four guys in Wylie, TX building a cocktail racer. We’re trying really hard to finish them soon so we can race them this summer. We have a facebook page “CCWBRA Bozman Farms Boat Racing & Yacht Club” where we post progress on our builds and have fun joking around. I decided to share my progress on the CCWBRA’s Forums page to maybe get suggestions and helps from you all that are more experienced. I found a 1985 8 hp Evinrude motor for my racer and it seems to run pretty good. I found the remote connectors for it on ebay and I’m already to connect it up. I’ll post more pictures as I progress but so far this is where I’m at. Thanks to those individuals that have already helped me out with all the questions I’ve had. This is really exciting to be a part of this group.

May 6, 2019 at 12:10 pm #11043

May 6, 2019 at 12:10 pm #11043 Christopher NormanMember

Christopher NormanMemberBen,

Your boat is coming along real well. It looks like you will be ready for the Tennessee Race. Would you let your group know that we moved the race to the 7th of September. I posted the update on the Forum today.

Thanks,

Chris Norman

May 6, 2019 at 1:02 pm #11044Ben Roper

ParticipantWe’ll see what we can do.

Thanks,

Ben

May 10, 2019 at 11:25 pm #11060 Jeffrey WeeberParticipant

Jeffrey WeeberParticipantBen, the boat is looking good! Great to see another group of enthusiastic builders. I am not the most experienced builder, but I would be happy to answer any questions I can or to point you to someone who can. I look forward to seeing you on the water!

May 16, 2019 at 4:26 pm #11089Ben Roper

ParticipantHere are some more updated pictures on my progress.

Before the fiberglass cloth.

Laid the cloth down and noticed a crease in the cloth that wouldn’t come out. I found out the other guys in our build have the same issue with their cloth. Looks like it was folded for a very long time and formed a crease.

Applying the epoxy was pretty simple and just like fiberglassing an RC airplane.

I messed up on my keel by not second guessing the instructions. I didn’t think about the predrilled holes not lining up when you put the bend in the keel (duh!). Also, I didn’t drill a large enough hole in my keel which caused the wood to split. I got frustrated because the epoxy was already starting to set so I had to hurry. Good thing about building with wood is that it’s easy to fix. Once painted, no one will know except for those who read this post. 🙂

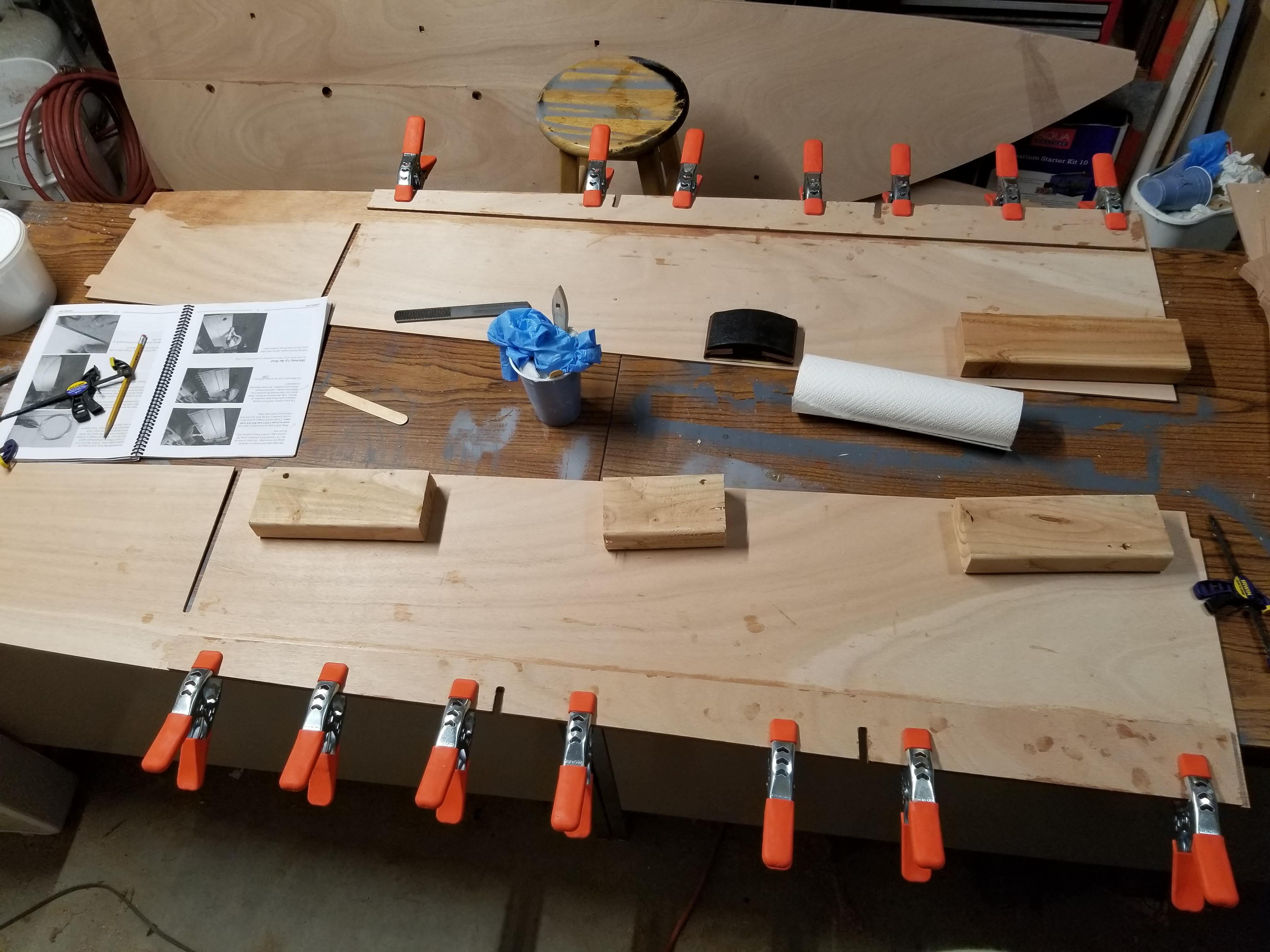

I was surprised how many clamps it takes to hold the wood in place.

The instructions say to round the wood piece in the front but then I found out that’s not a good idea. I fixed it by adding some wood flour to the nose and I think it’ll turn out fine. Once the top goes on, I’ll be able to see where to round the nose. Most of that pointed nose will go away then.

I sure do love this boat and can’t wait. 🙂

May 24, 2019 at 2:26 pm #11114Ben Roper

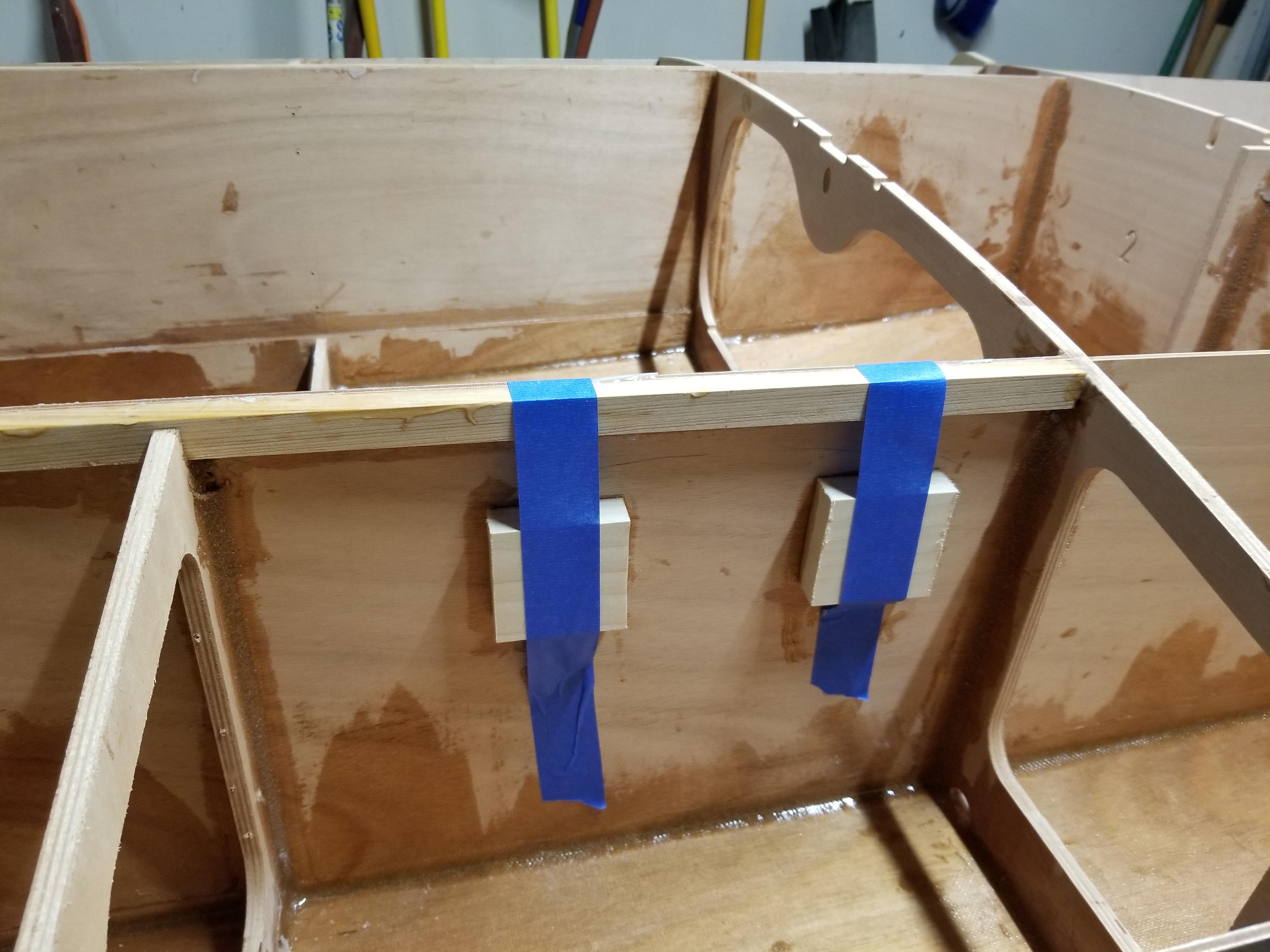

ParticipantGlued the flooring in for the cockpit.

Test fitting the top pieces. I sure do love the look of the grain on that wood. Definitely will have to varnish the top instead of painting it.

Putting the coats of epoxy on the underside.

My daughter Gracie came out and helped me glue the top on. We had a race putting the clamps on. It came out great and she was a big help. Definitely a two person job.

May 24, 2019 at 3:04 pm #11115

May 24, 2019 at 3:04 pm #11115Ben Roper

ParticipantI’ve been trying to gather ideas on a butt cushion/seat for my racer. I’m afraid I may kill my knees if I don’t have anything. I found this seat at Bass Pro Shops and I think it may work out well. I’m going to build a stand to hold the seat cushion out of wood underneath it just like this plastic stool. The plastic stool is 7″ high and because of the rectangle shape it won’t tip backwards. When kneeling my legs run along side of the stool and my behind can rest on it if needed.

I’m going to make it removable in case I don’t like it or if I need to make changes. It’ll be tether to the boat but it’ll just sit loosely in the cockpit. I think the weight of it, the floor cushion, and it resting between my legs, it shouldn’t move too much. Do you guys think that’ll work?

May 25, 2019 at 12:19 am #11116

May 25, 2019 at 12:19 am #11116Terry K (TK) Walker

ParticipantBen, There are a number of racers who have knee problems… What they do is add a seat that they straddle like a Motorcycle seat (Kinda) this way you can clamp your thighs around it which you will need to in the “G” force turns you will be making and not actually putting pressure on your knees .. .. The seat in the pic will be useless … You won’t stay in it after the first turn… Contact Fred Allerton… He has a pretty good set up for this kind of set up …

Everything looks good on your build … Do what you can do and all of you Texas Boys come on down to Tennessee .. trial and error then learn from your mistakes … Tennessee Moonshine “888” is in the same boat … No Pun intended .. New for us but we will make the Nationals in our on rig this year..

You are on pace with your build … You have plenty of time to build and trial/test … Looking forward to helping and meeting you Guys !!

Remember, Bowie, Crockett, and Houston … All Came to the aid when needed … And nothing has changed …. TK

May 25, 2019 at 9:20 am #11117Marty Calon

ParticipantWow, nice collection of clamps! I still have Jeff Weeber’s big box of PVC pipe clamps. If anyone needs them to build a boat, contact me.

You’re making great progress, and the pictures are good. Thanks for posting them.

Jack and I made the same mistake on #150 with the rounded bow. We rounded it too soon. The instructions are misleading about it. Luckily for all of us, epoxy takes care of it, and the deck covers it. In our case, we also filled some other small “unintended” gaps in other areas with epoxy, and the boat has turned out quite well so far.

We also had creases from the fiberglass, which I think will disappear or at least become very much less noticeable when it’s finished.

The seat is a great idea. I’m going to consider that too.

June 11, 2019 at 11:38 am #11153Ben Roper

ParticipantFiberglassing the top of the boat. I used the middle section of fiberglass to glass the bottom of the cockpit. It makes it much stronger without adding much weight. We were worried that us big fat guys will break the flooring.

I really like the round burrell on the top of my boat but sad about its location. My racing strip will cover it up.

Test fitting my motor to see if the angle of the transom block will work. I used Oak with a 10 degree angle.

Finally the second coat of epoxy was applied.

I’m ready to do a final light sanding to take out any epoxy runs and rough up the surface for the paint and varnish.

July 8, 2019 at 10:49 am #11349Ben Roper

Participant

I can’t remember which coat of paint this was but I’m using Rustoleum Marine Grade paint because of the price. I’m sanding between each coat.

I haven’t sanded the final coat but it turned out okay. I plan on doing three coats of paint and then three coats of varnish on the bottom.

Little bit of an orange peel texture but I haven’t sanded this coat yet.

Masked off to paint my graphics.

A little bit of the paint peeled off but overall I like the look. Now I need to add my numbers (yellow paint) and do 6 coats of varnish on top. I’m still using the Rustoleum Marine Grade Varnish.

August 3, 2019 at 6:51 pm #11535

August 3, 2019 at 6:51 pm #11535Ben Roper

ParticipantVarnish is done and I’m working on installing everything. My boat inspection is on the 9th. This is so much fun! I love it!

August 4, 2019 at 7:01 pm #11540

August 4, 2019 at 7:01 pm #11540Marty Calon

ParticipantVery nice! Congratulations on a great project!

August 15, 2019 at 9:15 am #11633Ben Roper

ParticipantI plan on doing the maiden voyage this Saturday. Fingers crossed that everything runs smoothly. (This was so much fun to build.)

August 15, 2019 at 11:35 am #11636

August 15, 2019 at 11:35 am #11636 Christopher NormanMember

Christopher NormanMemberReal Nice! Inaugural Race and christening in Tennessee?

-

AuthorPosts

- You must be logged in to reply to this topic.